Meru has led from the front through innovation and advanced technology in revolutionizing the sugar industry over the last three decades. This has been achieved through persistent focus on safety, reliability and productivity. High efficiency products from Meru – Milling Plants, Boilers, Continuous Pans, Falling Film Evaporators, Refineries and other process house equipments enable sugar factories to optimize capacity and efficiency, while increasing capacity, steam economy and quality of sugar.

Meru Industries undertakes all types of sugar plant projects – right from selection of equipments, design, manufacturing, supply and erection to commissioning.

Meru provides unmatched expertise in the area of expansion of existing sugar plants through renovation and modernization while integrating with new equipment for increased capacity, efficiency and production quality.

Over a period of over 27 years, we have over 150 satisfied customers with plants ranging from 1250 TCD upto 15000 TCD.

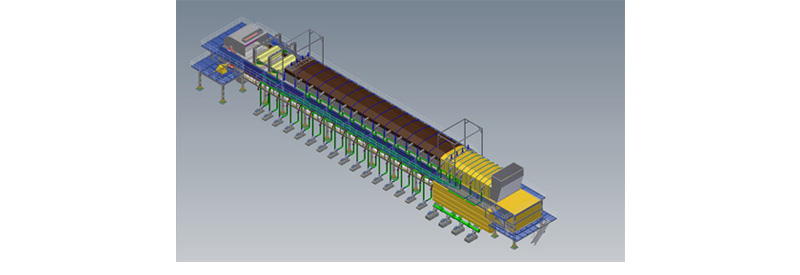

■ Meru Industries is a specialist in cane preparation devices with greater energy efficiency.

■ We install mill sizes that range from 24" x 48" to 55" x 110" with the least apex angle in the industry.

■ Meru's mill technology has high transmission efficiency with reduced energy consumption in pinion less mill. The energy consumption is lesser than 15% over the conventional systems in practise. Increased life of mill roll shaft is attained due to very low stress levels alongwith a negligible chance of fatigue or stress corrosion failure.

■ Better extraction can be attained due to uniform compression of cane blanket and feasibility of operating the mill at lower surface speeds.

■ Margins to upgrade the mill size by resheeling of mill rollers with higher size is provided.

■ All equipments are designed with two major considerations - ease of operation and maintenance. Meru designs also include provision for capacity enhancement of the milling plant.

■ Equipments are pre-assembled before delivery to reduce the installation time. The transport system for sugar cane bed is continuous.(i.e. moving bed).

■ Juice extraction is done using variable flows while recirculation flow is stationary. The flow of recirculation juice which passes through the bed in each stage can be adjusted to flow rates that are greater than the net flow of juice produced.

■ The imbibition system of juice over the bed in each stage is evenly distributed and intermittent. This helps to obtain a homogenous distribution of juices across the whole sugar cane bed.

■ Two sets of horizontal bed lifters distributed along the bed ensure that there is no compaction in the bed.

■ The automatic sugar cane feed system ensures no recycling of sugar cane. This includes a leveling system with adjustable height control to provide an evenly distibuted bed with optimum height.

■ A system to heat and control the temperature of the diffuser using direct or indirect steam on each stage is provided. The diffuser has 18 diffusion(washing) stages and 2 draining stages.

■ In this age of co-generation, steam is as valuable as money. Lesser the steam consumption, higher is the efficiency and output for co-generation.

■ Meru designed Boiling House primarily focuses on reduction of steam consumption.

■ Meru uses a mix of modern technologies like low head vaccum pan, falling film evaporators, vertical crystallizers, batch and continous vaccum pans and dynamic juice heaters to attain the same.

■ Minimizes sugar losses during evaporation.

■ Meru uses modern recovery systems and equipments like Cigars, Condensate Recovery system, Direct Juice heaters, Condensate Juice heater etc.

■ Continuous upgrading and modernization of equipments and plants is an area which is vital in the sugar industry.Constant evolution of ideas and technology is the backbone for the functioning of Meru.

■ Increasing capacity and efficiency without high investments without discarding the existing equipment is a core philosophy followed at Meru.

■ Equipments like rope couplings, fiberizers, planetary gear box, etc. are used for the same.

■ Meru is the market leader in enhancing capacity of existing Mills with installation of Pressure Feeders like G.P.R.F and T.R.P.F etc.

■ Sulpherless sugar

■ Lime consumption is lower

■ Scaling in Evaporators is reduced due to lower Inorganics loading

■ Purer massecuites give flexibility in grain size / colour of sugar.

■ Low Suspended Matter/Ash/Turbidity make sugar attractive for Industrial users.

■ Sugar quality of EU1 & EU2 grade.